Partnership with

Lutz Blades

A Trusted Collaboration Delivering World-Class Cutting Performance

For over a century, LUTZ BLADES has been a global name in high-performance industrial blades and knives. Since 1922, their German-engineered blades have been recognised for exceptional precision — from razor-sharp profiles for the finest cuts to extremely stable edges designed for pressure-based, impact-heavy cutting applications.

IMC Industries is proud to be the Exclusive Partner of Lutz Blades in Malaysia since 2019. Through this strong long-term partnership, we provide Malaysian industries with premium cutting solutions that deliver unmatched durability, accuracy, and reliability.

Our customers benefit directly from Lutz’s century-long expertise, combined with IMC’s local industry experience and technical support — ensuring blades that last longer, perform better, and cut more efficiently.

Lutz Partner Conference 2025

LUTZ BLADES Partner Conference 2025 held in Solingen-Germany. Around 50 participants – all around the world – came together to exchange ideas on current topics, strategies, and shared goals.

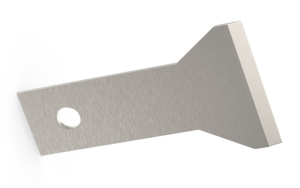

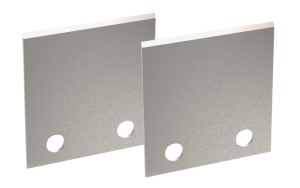

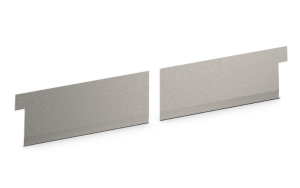

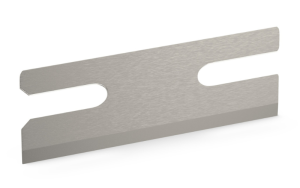

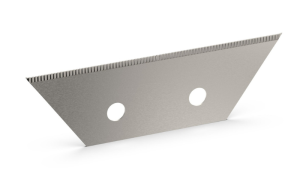

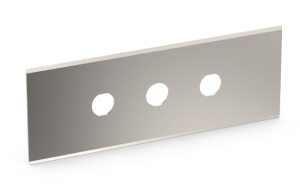

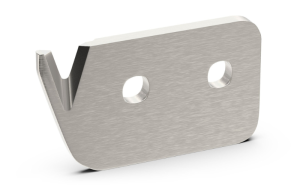

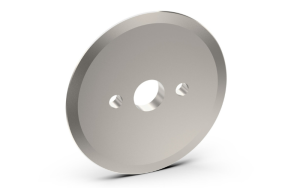

Blades by Industries

Industry

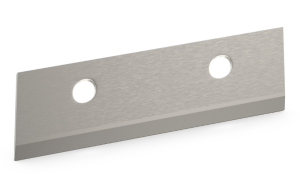

Blades for Industrial Applications

Medicine and laboratory

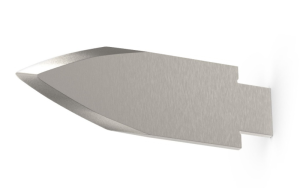

Blades for Medical Applications & Laboratory

Tool trade

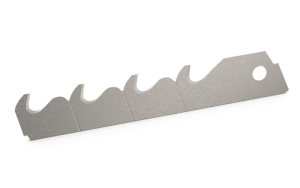

Blades for Tools Trade Applications

Food production

Blades for Food Productions Applications

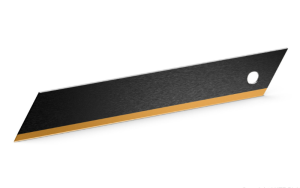

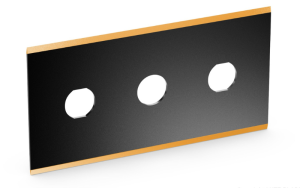

Coating Program

TiN (Titan-Nitrid)

Standard hard material with high wear resistance and relatively high coefficient of friction (against reference material steel approx. 0.4 to 0.7), usually gold-colored, safe application range up to approx. 300 °C.

TiC (Titan-Carbid)

Has lower wear resistance than TiN with significantly lower coefficient of friction (against reference material steel approx. 0.3 to 0.5), usually anthracite colored.

TiCN (Titan-Carbonitrid)

Intermediate coating material between the high wear resistance of TiN and the low coefficient of friction of TiC, relative position between TiN and TiC depending on the ratio of C and N, usually anthracite color.

TiAlN (Titan-Aluminium-Nitrid)

Has greater oxidation resistance than TiN with comparable coefficient of friction, usually anthracite blue.

DLC (Diamond-like Carbon)

Has high wear resistance with low coefficient of friction (approx. 0.1 against reference material steel); susceptible to impact loads and high temperatures (between 100 and 300 °C depending on structure).

PTFE (Poly-Tetra-Fluor-Ethylen) – Teflon®

Teflon® non-stick coating (PTFE); due to the very low surface tension, practically no foreign bodies stick to the cutting edge, resistant to acids and alkalis; significantly reduced frictional resistance; the very low static friction allows jerk-free cutting (therefore very suitable for the medical sector); low wear resistance; not suitable for contact with sodium and at temperatures above 250 °C.

Color varnish

Applied over the entire surface, serves as a sorting aid for different material thicknesses and as corrosion protection.

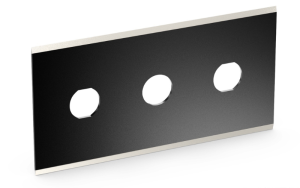

Blueing / Blackening

Applied over the entire surface, light corrosion and starch protection, also serves as a distinguishing aid.

Call us now or request a quotation

Let’s Shape Your Edge Together

Partner with IMC Industries Sdn Bhd today and discover Malaysia’s most advanced industrial cutting solutions.

Contact Us

- Temasya Industrial Park, 16, Jalan Penyair U1/44, Hicom-glenmarie Industrial Park, 40150 Shah Alam, Selangor, Malaysia

- Phone: +603-5569 7585

- E-mail: enquiry@imcindustries.com

Working Hours:

Monday – Friday : 9:00am – 6:00pm

Saturday: 9:00 am – 1:00pm

Sunday: Closed

For further queries about our services, please send email and we will be in touch within 24 hours.