Our Services

For extremely fine cutting jobs to extremely robust for impact and pressure cutting actions. Together with the customer, we define all the relevant parameters to ensure your individual requirements are met – to provide greater sharpness and better service lifetimes.

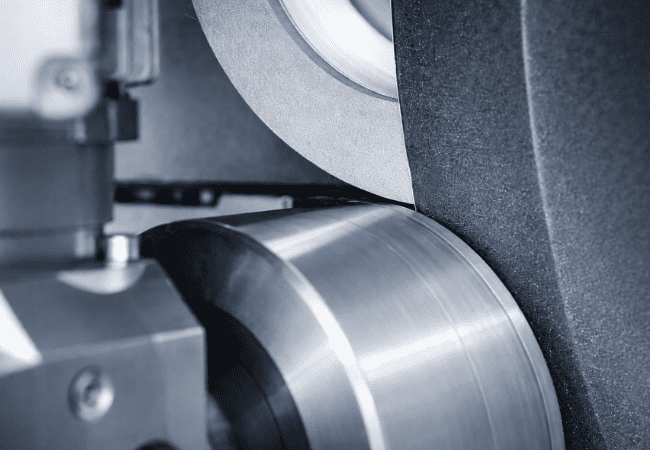

Resharpening of industrial knives

We restore worn and damaged knives to the closest geometric accuracy through precision sharpening. Our process improves:

- Dimensional consistency

- Concentricity and surface finish

- Edge sharpness and uniformity

The restoration service is a cost-saving alternative for purchasing new knives and blades for our customers.

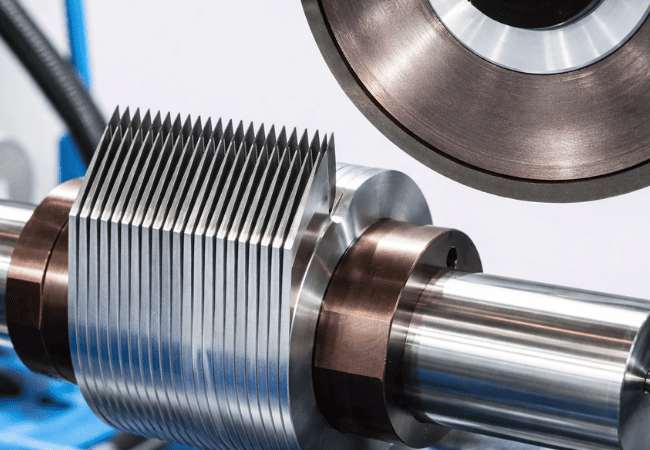

Knives Reprofiling & Tool Reconditioning

For knives that exceed the scope standard resharpening dimension size limit, we offer reprofiling services that include:

- Radius correction and precise edge-angle adjustment

- OD/ID correction

- Web-path-aligned regrinding

- Reconditioning of machine knives

Our reprofiling service restores tool performance, even after heavy wear, damaged or improper sharpening.

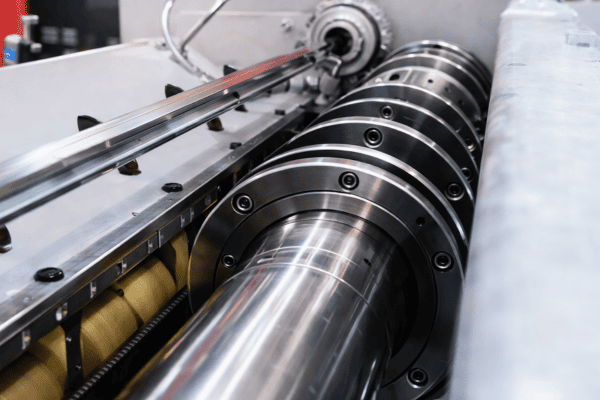

Knife holders Customization

We customize industrial knives holder to meet cutting process requirements based on specific dimensions, materials and mounting systems for various machinery and industrial process applications.

For slitting process (e.g., cutting process in metal, paper, or plastic industries), custom cutter units and holders designed to ensure stable contact pressure and optimal slitting quality.

Rapid Prototyping of Custom Blades

We provide rapid prototyping solutions for our customers requesting customized blades, knives or design modifications.

Our engineering capabilities include:

- CAD/CAM design

- Dimensional evaluation

- Material consultation

- Trial knives and blades

- Prototype-to-production development

This service is applicable for R&D teams, machine manufacturers and customer seeking for OEM cutting tool brands.

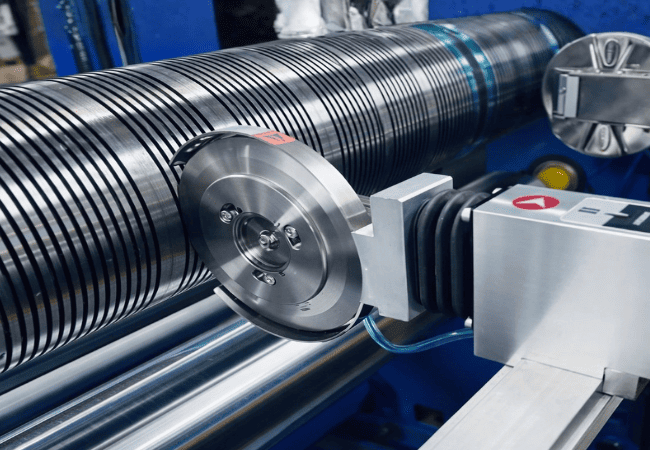

slitting system design

As slitting system design involves a specific selection of cutting tools and customised process determined by cutting materials, required precision and production speed, our expert provides consultancy service for well-designed slitting system to ensure stable web tension, precise cut, and efficient rewinding of the material into narrower rolls.

various machine types

IMC Industries specializes in knife and blade solutions tailored to various brand of industrial machine

Atlas®

High-precision film slitting and winding machines used in flexible packaging and film production.

Barmag®

Advanced fiber-spinning and texturing machinery for textile and technical yarn industries.

Goebel®

Reliable slitting and rewinding machines for film, paper, and foil converting.

Brückner®

Leading BOPP/BOPET film production lines for packaging and industrial films.

Kampf®

High-performance slitting and rewinding systems for films, foils, and laminates.

Reifenhäuser®

Extrusion and blown-film equipment used widely in packaging and industrial film production.

SMI / Lenzing®

Fiber and nonwoven processing technology for textiles, hygiene, and eco-fiber industries.

Starlinger®

Machinery for woven PP bags, raffia tape lines, and plastic recycling.

Windmöller & Hölscher® (W&H)

Premium extrusion, printing, and converting machines for flexible packaging.

Call us now or request a quotation

Let’s Shape Your Edge Together

Partner with IMC Industries Sdn Bhd today and discover Malaysia’s most advanced industrial cutting solutions.

Contact Us

- Temasya Industrial Park, 16, Jalan Penyair U1/44, Hicom-glenmarie Industrial Park, 40150 Shah Alam, Selangor, Malaysia

- Phone: +603-5569 7585

- E-mail: enquiry@imcindustries.com

Working Hours:

Monday – Friday : 9:00am – 6:00pm

Saturday: 9:00 am – 1:00pm

Sunday: Closed

For further queries about our services, please send email and we will be in touch within 24 hours.